TRIBOLOGY

Solutions that make technology run smoothly.

We all know how important friction losses are in everyday life. In the world of technology, the science of tribology keeps friction to a minimum – and increases the service life of components. Since 2002, H-O-T has been developing technologies to optimize friction-related processes. The Buttenheim Center of Excellence, which was opened in 2005, creates thin coatings with great success. H-O-T tribo-coatings are used worldwide wherever precision and performance are crucial.

Thin layer – big effect:

We have the right solution for your production

With tribological coatings precisely tailored to your requirements, friction can be reduced to the minimum that is technically feasible.

H-O-T offers solutions for all sectors in which optimizing friction and wear properties is of high importance. From general machine elements to components that have to withstand extreme conditions – for example in motor sports.

Tribological coatings open up great saving potentials for you.

We make sure you can make optimal use of them.

With our H-O-T coatings, you can reduce the use of energy and materials, the cost of production and maintenance – and save valuable energy and raw materials.

Developed for optimal properties

The H-O-T process for tribological coatings

H-O-T tribo-coatings can specifically enhance surface properties without influencing the underlying material. The coating process temperature is approx. 180°C (however lower temperatures are also possible). Tribological coatings and the PVD/PACVD processes are environmentally friendly.

H-O-T tribological coatings offer excellent potential for the design of highly stressed components with improved performance.

Less friction.

Less wear.

More performance.

H-O-T tribo-coatings can improve specific surface characteristics – without affecting the underlying material.

Economical and eccicient:

Production on H-O-T coating machines.

H-O-T uses state-of-the-art PVD/PACVD machines for the deposition of tribological layers.

All processes are environmentally friendly.

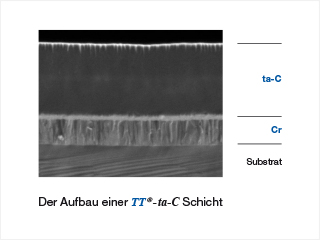

TT®-TA-C

TT®-ta-C coatings are a sub-group of the amorphous, diamond-like carbon coatings (DLC – Diamond-Like Carbon). TT®-ta-C is a tetahedral, amorphous, hydrogen-free carbon coating that is extracted from fixed carbon (graphite) by means of laser arc technology (PVD process).

| Coating structure: | Hydrogen-free, tetahedral, amorphous carbon, sp³ content adjustable above 85 % |

| Hardening: | 4500–7000 HV, adjustable |

| E-modulus: | 300–450 GPa, adjustable |

| Coefficient of friction: | 0.05–0.10 (dry on steel) |

| Wear coefficient: | 1*10-8 mm³/Nm (dry on steel) |

| Temp. resistance: | 400– 500°C in air, <800°C in vacuum |

| Coating thickness: | 0.1–4.0 μm |

Engine components

Injection systems, diesel, injection pumps, valve drive, crank drive, pistons and cylinder pairings

Advantages:

- Increases service life and capacity

- Little to no lubricant consumption

- Dry systems

- Fuel savings

- Simpler construction

Motor racing

Chassis, drive train, engines

Advantages:

- Increases service life and capacity

- Substitution of parts

- Lightweight construction

- Extreme component stress

Bearing elements

Rolling, sliding, ball bearings/guiding elements

Advantages:

- Protection from inadequate lubrication

- Dry systems

- Increases service life and capacity

Drive elements

Gear wheels, shafts, axles, chains, worm gears

Advantages:

- Increases service life and capacity

- Greater torque with smaller components

Machine tools

Bearings, slides, spindles, deflection rollers

Advantages:

- Less maintenance

- Increases service life and capacity

General mechanical engineering

Compressors, compactors, pumps, valves, fittings

Advantages:

- Uses more environmentally friendly media

- Increases service life and capacity

Plastic injection molding machines

Cores, ejectors, slides

Advantages:

- Better demolding

- Better sliding

- Optimization of the flow process of the molding compound of textile machines

- Abrasion protection

Presses

Pneumatic valves

Advantages:

- Increases service life and capacity

Food industry

Bearings/dosing pistons/guides

Advantages:

- Lubricant-free production

Medical technology

Scissors, forceps, bone drills

Advantages:

- Sterility

- Corrosion protection

Tribological coatings for tools

In the fields of tool-making, machine and mold construction and the machining of aluminum, we favor TT®-DLC and TT®-C-DLC as tribological coatings.

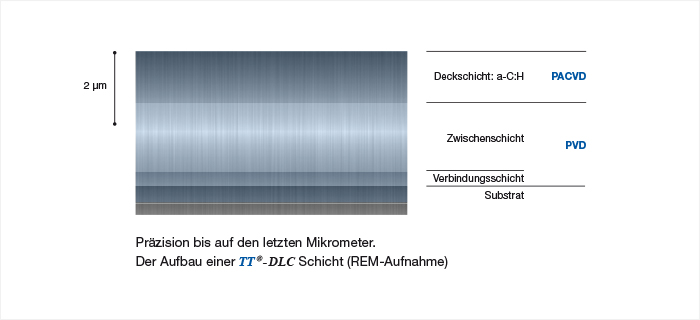

TT®-DLC is a metal-free diamond-like layer of carbon and is deposited at low temperatures using the PACVD process. The combination of good wear-resistance and outstanding frictional and non-stick properties makes TT®-DLC coatings an ideal surface treatment for components and tools subject to high frictional forces.

TT®-C-DLC coatings are a sub-group of the amorphous, diamond-like carbon coatings (DLC – Diamond-Like Carbon). Unlike the majority of the commercially available TT®-DLC coatings, they are not deposited from gaseous hydrocarbons (e.g. acetylene or methane) using the plasma-activated CVD process (PACVD-Plasma Assisted Chemical Vapor Deposition). They are produced using the PVD process (Physical Vapor Deposition) by sputtering a carbon target. The addition of reactive gases during the coating process enables the hydrogen content and therefore the mechanical and tribological properties of the coating to be adjusted to optimize the properties for the application in question.

TT®-C-DLC coatings can achieve both a higher hardness and a lower coefficient of friction than the TT®-DLC coatings deposited by the PACVD process. The properties of TT®-C-DLC coatings are summarized in the table.

TT®-C-DLC coatings are normally deposited with a thickness of 1.5 ± 0.5 μm. Because of their properties, TT®-C-DLC coatings are readily used when manufacturing standard components.